The Buzz on Inventory Management

Wiki Article

The Best Strategy To Use For Inventory Management

Table of ContentsThe Best Strategy To Use For Inventory ManagementInventory Management for DummiesThings about Inventory ManagementNot known Incorrect Statements About Inventory Management

JIT supply management can be dangerous. If demand unexpectedly surges, the manufacturer might not be able to source the supply it requires to satisfy that need, harming its credibility with clients and also driving business towards competitors. Even the smallest delays can be problematic; if a vital input does not arrive "simply in time," a bottleneck can result.

The EOQ model seeks to ensure that the correct amount of stock is bought per batch so a firm does not have to make orders too often as well as there is not an extra of stock remaining on hand - Inventory Management. It thinks that there is a compromise between supply holding prices as well as inventory arrangement prices, as well as complete stock costs are reduced when both setup prices and holding costs are decreased.

DSI is likewise called the ordinary age of supply, days inventory outstanding (DIO), days in inventory (DII), days sales in stock or days supply and is translated in multiple ways. Showing the liquidity of the supply, the number stands for exactly how numerous days a firm's current supply of inventory will last.

Inventory Management Fundamentals Explained

If a business often changes its approach of supply audit without affordable justification, it is likely its management is attempting to repaint a brighter image of its service than what holds true. The SEC requires public companies to disclose LIFO reserve that can make supplies under LIFO costing comparable to FIFO setting you back.This can likewise elevate red flags with a business's capability to stay affordable and manufacture items that appeal to customers going forward. The four kinds of inventory monitoring are just-in-time management (JIT), products need preparation (MRP), financial order quantity (EOQ), as well as days sales of inventory (DSI). Each inventory administration style works much better for different companies, and there are pros as well as disadvantages to every kind.

"Supply is like dairy items," Cook is quoted stating. For this reason, stock administration can save a business millions.

Inventory administration is an essential component of business operations. Correct stock administration depends on the kind of company as well as what sort of item it sells. There might not be one best type of supply management, because there are pros and disadvantages to each. Taking benefit of the most fitting type of inventory management design can go a long way.

6 Easy Facts About Inventory Management Described

When it comes to supply monitoring, there's good news and there's negative information for many services. Inventory administration can be a daunting task, which is why business commonly avoid re-evaluating their processes.While it might be appealing to follow a status-quo method, your stock administration system can really make or break your organization applying an effective and also reliable system can be a surprise trick to success. Inventory Management. What is Stock Administration? Continue reading to find out why supply management systems visit their website matter and also how you can utilize the right system to assist your service be a lot more effective and successful.

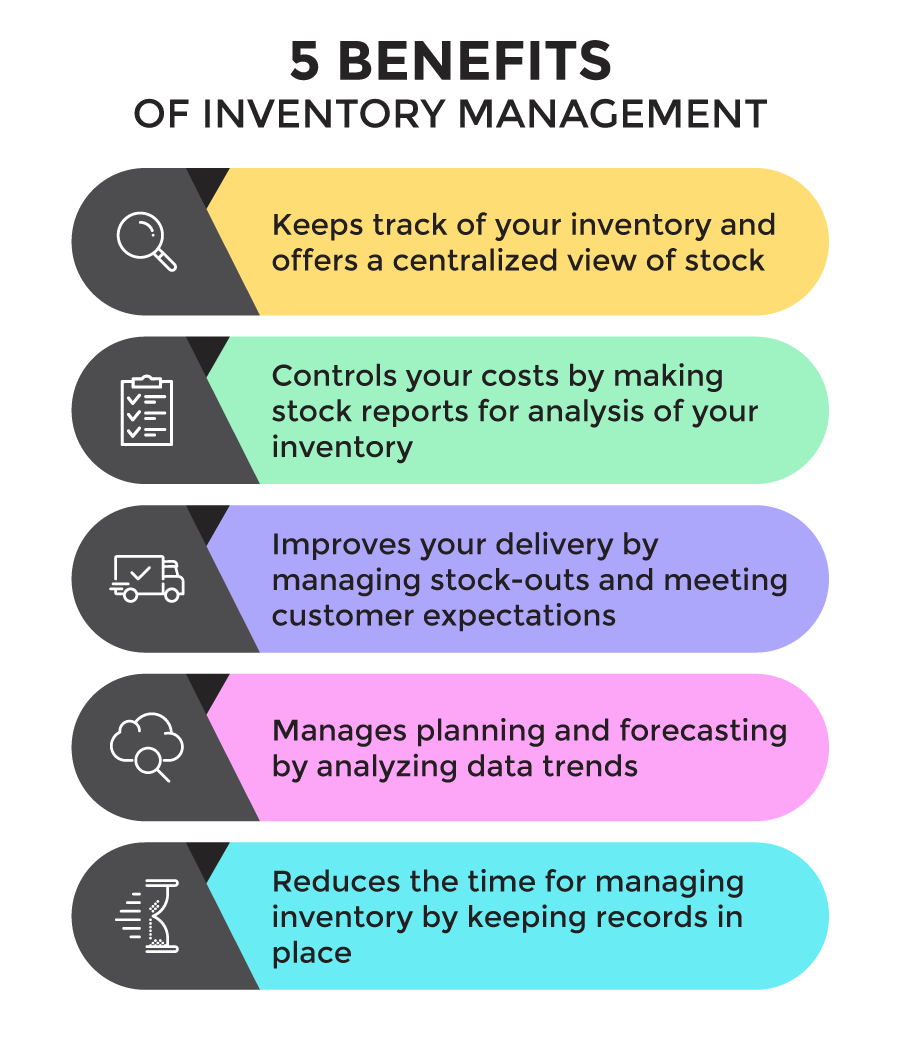

Supply monitoring, nonetheless, is greater than simply a simple tally of stock. A well-managed inventory system allows your service maximize its storage areas, better serve clients by having the supply that they want (when they want it), as well as conserve cash by minimizing costs as well as losses as a result of perishing and also theft.

Efficient supply monitoring can be a valuable device, offering insight into crucial aspects of your service, consisting of: Your economic standing, Client habits, Product as well as service opportunities, Future trends To reveal the power of stock management systems on business success, allow's transform to the striking instance of Kmart and Walmart during their rate battle in the 1990s - Inventory Management.

Some Known Facts About Inventory Management.

Their appropriately named "just-in-time stock" system minimized excess inventory, which released up money that might then be spent into business growth. In addition, this more-efficient system provided far better understanding right into client demands that made it Our site possible for the firm to provide more of the products that customers wanted at a lower price as well as a lower price for clients.During the same time duration, Kmart stuck with their traditional stock administration procedure. The results represent themselves: Between 1998 as well as 2000, Kmart stock costs went down 63%, while Walmart stocks increased by 82%. In the early 2000s, Kmart's decline proceeded. The company declared personal bankruptcy in 2002, shut hundreds of Kmart shops, and also eventually combined with Sears Roebuck in 2005.

While the particular sort of inventory that your service deals with might vary substantially depending upon whether your business is focused on wholesale, retail, or production, the fundamental principles of just how you manage stock are universal. If we think about inventory as cash, taking control of your supply and optimizing what you have (while lessening supply aka money waste) discover this is key.

In order to develop higher visibility of supply degrees, a reliable inventory management system must utilize aspects like: You'll additionally want to examine the kind of inventory management system you use as this can impact how well you see your stock. In order to much better comprehend exactly how well your stock system is offering your service, let's look at 2 key methods to managing your supply: periodic and also continuous supply systems.

Report this wiki page